From the Stone Age, the Bronze or Iron Ages to the Silicon Age in which we now live, every major progress in human civilization has been driven by the evolution of materials. New materials are needed to improve the quality of life, ensure a sustainable environment and reduce human impact on the planet. Research and discoveries in the materials science and engineering sector ensure this progress.

The World Economic Forum (WEF) has developed its Strategic Intelligence capabilities to help make sense of the complex forces driving transformational change across economies, industries, and global issues. One of the developing fields in the sector of advanced materials is 3D printing which has already revolutionized the manufacturing industry. However, now we can be amazed by other applications of the three-dimension printing technology: bioprinting human organs, printing affordable housing, and the on-demand production of potential future habitats on the Moon and Mars. Sounds a bit like science fiction? Well not anymore.

3D printing is already engaged in the medical sector and the outcomes are truly mesmerising. Solutions for the field are also being created at Kaunas University of Technology (KTU). PhD student at the Faculty of Mathematics and Natural Sciences (FMNS) Antonio Jreije is developing new materials which can be used for printing medical phantoms.

Antonio, what is the importance of new advanced materials in the medical field?

The medical device industry is at the peak of technological advancement with undergoing research in diagnostics, patient safety and health monitoring devices, surgical devices, orthopaedics, biomedical and cell regeneration devices. The requirements of today’s complex devices necessitate the development of new advanced materials.

Factors such as material biocompatibility, sterilisation, ageing, recycling, and reusability are all considered essential and must be taken into consideration. Additionally, the evolution of fast prototyping, additive and subtractive manufacturing, 3D printing, automation and artificial intelligence has been a major driver for innovative materials in the medical field.

Partially, the use of 3D printing for medical applications is expanding rapidly with the aim of personalized treatments and precision medicine. Research in 3D printing involves the development of surgical tools, personalised orthopaedic implants and prosthetics, medical phantoms as well as tissue engineering.

Medical phantoms? Could you tell me more? What are they and what their purpose?

Medical applications of radiation have enhanced the diagnosis and treatment of various medical conditions while accounting for more than 95% of radiation exposures from artificial sources. However, there are risks associated with the use of ionising radiation especially at higher doses such as the development of cancer later in life.

Therefore, it is essential to maintain the safety of the patient by using medical phantoms for the evaluation of medical devices that deliver ionizing radiation. Phantoms are physical structures designed to replicate the biological tissue in terms of shape and interaction with radiation. Medical phantoms used in the clinical setting vary in shape from standard glass cylinders filled with water to complex anthropomorphic phantom mimicking the human body with high accuracy.

In diagnostic radiology, these devices help in the optimisation of the imaging procedures by ensuring that the patient dose is “as low as reasonably achievable”. In addition, phantoms are used in radiation therapy for pre-treatment planning to verify that the calculated radiation dose can be delivered safely to the tumour while sparing nearby tissues and organs.

Please, tell me more about your research aimed at developing these materials.

Interest in 3D printed patient-specific phantom for pre-treatment quality assurance in radiotherapy only started a few years ago. Patient-specific phantoms are superior to commercial phantoms in minimizing dose errors and improving treatment-planning outcomes. To ensure that the phantom replicates the patient geometry, heterogeneity of the human tissues in terms of electron density must be considered.

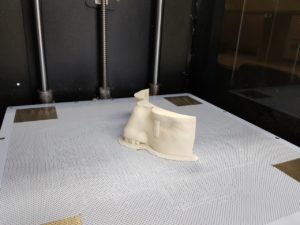

Current 3D phantoms are printed using commercial filaments such as Acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA) which mimic soft tissues (fat, thyroid, white and grey matter, etc). Nevertheless, these materials failed to replicate the properties (density and radiation attenuation) of human bones even when varying their printing parameter.

Thus, the main focus of my research is the characterisation of new materials that exhibit bone equivalent properties and can be successfully employed in fused deposition modelling.

What knowledge and skills are required for such research?

Interdisciplinary research integrating knowledge from the different scientific field is becoming more important. This concept applies to my research that necessitates knowledge in material science, physics, engineering, biology and chemistry.

Experience in computer modelling, creative thinking as well as problem-solving skills are necessary for successful material research. Shortly, the first step involves the development and characterization of printing materials with desired properties (i.e. physical density, imaging attenuation, dose distribution, etc).

This is followed by the extrusion of the material into filaments for 3D printing. The 3D filament will undergo extensive evaluation and quality control to determine its mechanical and thermal properties.

Could the outcome of your research have an impact on medical physics?

Commercial anthropomorphic phantoms based on moulding and casting are expensive (starting from around €20.000) and not all health care facilities have the financial resources necessary to purchase these devices.

Recently, additive manufacturing has become a widely available and affordable technology costing between €1.500 and 5.000 for professional 3D printers. By demonstrating the utility of 3D printing in radiotherapy and by developing new printing materials, 3D printing technology can be introduced into healthcare facilities. This can be beneficial for the in-house production of cost-effective 3D printed phantoms based on the special needs of each hospital.

What are your expectations?

In medical science, the ultimate goal is an optimisation of treatment outcome and maintaining patient safety. In the case of radiotherapy, pre-treatment planning is the most important step in ensuring optimal delivery of radiation to the tumour while saving the healthy tissues from the detrimental effect of ionizing radiation.

3D printing of patient-specific phantoms will enable to predict dose distribution to clinical target and organs at risk more accurately which lead to a higher level of tumour control and less chance of tumour recurrence. Moreover, the reduced cost of this technology will facilitate access to high-quality radiotherapy for everyone.

It seems that the research you conduct is truly promising.

Indeed, it seems so. My research group under the supervision of Prof Diana Adlienė have developed many innovative materials that have application in the field of medical physics including modified dose gels for evaluation of 3D dose distribution and flexible lightweight shielding devices for radiation protection.

Investigation of the feasibility of 3D printing usage in radiotherapy started in 2018. It should be noted that in addition to the fabrication of medical phantoms, an in-house algorithm was programmed for the reconstruction of the patient-specific phantom from acquired Computed tomography images with high accuracy.

Also, the use of 3D printing for patient-specific boluses in radiotherapy was proven successful. These bolus devices were customised specifically for each patient and manufactured using a 3D printer to improve dose coverage of superficial tumours.